Insights

How and When to Use Antimicrobial Materials

By Dennis Hacker

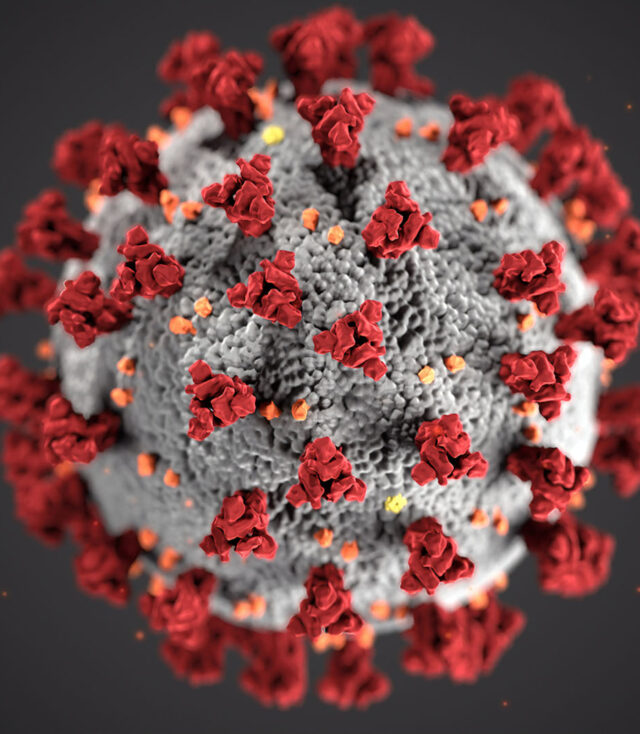

Many of us are asking about what we can do to stop the spread of viruses, bacteria, mold and mildew. We might have heard of antimicrobial coatings being used to stop the spread of infectious disease in a healthcare setting, but will they help in learning environments? Fanning Howey continues to study their use, but here is what we have found out so far. In some cases they may be worth consideration and the investment.

What are Antimicrobials?

Antimicrobials inhibit the ability of microorganisms to grow on the surface of a material. They may not kill the bacteria, but inhibit it from growing. In general, something that is antimicrobial could have a detrimental effect against a range of organisms both beneficial and harmful. The ability to selectively combat certain microorganisms while having little detrimental effect against others dictates the usefulness of a particular antimicrobial agent.

Antibacterial vs. Antimicrobial

The primary difference between antibacterial and antimicrobial is the types of microorganisms they act on. Antibacterial technologies are effective against a broad spectrum of harmful bacteria. We are familiar with them in the form of wipes, soaps and cleaners, to name a few. They can kill the bacteria. Antimicrobial technologies minimize the presence of bacteria, mold, and fungi. Antimicrobial substances offer a greater level of product protection by continuously inhibiting the growth of microbes on surfaces for very long periods of time as reported by Microban.

When to use Antimicrobial Coatings and When to Avoid Them

It is important to understand that viruses like COVID-19 are an infectious disease that antimicrobial coatings are not proven to prevent from spreading. In certain high touch surfaces they may supplement risk when regular cleaning is impractical.

Frequently-touched surfaces that should be constantly cleaned include: door hardware, lockers, toilet room partitions, faucets and sinks. While some of these can be designed to be touchless often these items will frequently need to be cleaned and disinfected.

Since it is not practical to clean every surface after every use, we might benefit from antimicrobial coated surfaces between cleaning and disinfection. We can liken it to using antibacterial hand lotions when we cannot wash our hands. Coupled with regular scheduled cleanings, antimicrobial coating creates an inhospitable environment for microbial growth by damaging the microbes’ cell walls.

In addition, this interferes with the conversion of the nutrients into energy inhibiting reproduction. The microbes die off and are not replaced within the population. By using antimicrobial coatings, you can decrease the buildup of microbes that cause stains, odors and deterioration of surface in addition to the spread of disease.

For recommendations on how to clean your products we recommend reaching for those Maintenance Manuals and carefully following the manufacturer’s recommendations. For disinfecting, we recommend following the Center for Disease Control (CDC) guidelines under “How to clean and disinfect,” which outlines easy-to-prepare bleach or alcohol solutions for disinfecting your facility.

Also a recent study cited in Architectural Record stated that there is little evidence that antimicrobial additives result in healthier occupants and warned that these additives may have negative impacts on both people and the environment. Additionally, people may avoid disinfecting in place of antimicrobial surfaces, which increase the spread of germs. It is important to make smart decisions when choosing which antimicrobial materials to implement and to continue a strict cleaning and disinfecting schedule.

Materials/Manufacturers to Consider

Look for products that are built to last. Several manufacturers listed below utilize preventative technologies that are non-toxic several that have been EPA-registered, NSF=certified, and some like ASSA ABLOY Microshield even FDA-approach for use with food preparation.

- Lintec paint coatings with antimicrobial protection.

- Lyon antimicrobial coating for their steel lockers.

- ASSA ABLOY MicroShield – an antimicrobial coating that delivers protection against a broad range of bacteria and microbes using silver ion technology

When choosing materials for high traffic areas, consider manufacturers that do their due diligence. Antimicrobial coating claims should be backed with research and certification.

Be Diligent with Cleaning

No matter what materials you choose to use, remember to continually clean and disinfect. Then clean and disinfect again. Supplement this with antimicrobial coatings on high-touch surfaces and only with products approved by the EPA, and those that are NSF-certified and FDA-approved. Avoid products that make shameful disease control assertions. And don’t forget to consult those Maintenance Manuals and CDC guidelines.

Smart Schools Roundtable: May Session Ohio

ByFor the May session of Fanning Howey’s Smart Schools Roundtable, we heard from two separate speakers for Indiana and Ohio. For Ohio, education consultant Paul Pendleton spoke about the future of Ohio schools in a

Full ArticleSmart Schools Roundtable: May Session Indiana

ByFor the May session of Fanning Howey’s Smart Schools Roundtable, we heard from two separate speakers for Indiana and Ohio. For Indiana, Barnes and Thornburg Partner Jeff Qualkinbush returned to discuss the Indiana legislative session

Full ArticleSmart Schools Roundtable: HVAC Indoor Air Quality

ByFor the April session of Fanning Howey’s Smart Schools Roundtable, we heard from ASHRAE Distinguished Lecturer David Schurk on how HVAC systems can improve and maintain indoor air quality to promote healthy learning environments. David

Full Article